LOF Defence - a manufacturing journey making body armour, tactical gear and running a business - part 1: The Chaos

My name is Darren, I am one of the three who started LOF Defence in 2016. Believe it or not, we’ve grown into a top-tier manufacturer of body armour and tactical gear that’s used across Canada and shipped all over the world to law enforcement officers and military units operating in some of the toughest war zones. Our equipment has saved lives, including law enforcement K9s that were protected from stabbing attacks thanks to our vests. Hearing personal stories from K9 officers who credit our gear with saving their dogs is one of the biggest motivators for us to keep pushing forward. It still amazes me how far we’ve come on this journey—especially when I look back at how we started a business in manufacturing without really knowing what we were doing.

When we first started, we had a small but extremely talented team. Our sewing was on point, our quality was top-notch, and we absolutely refused to let any defective product slip through to a customer. We had some modern body armour designs that we felt really good about, and our K9 line—especially the StreetFighter—was something we were proud of from day one. Looking back at our little company, I’m mind blown by the growth we experienced and how necessity and pure desperation led us to learn, understand and embrace “Lean Manufacturing.”

Manufacturing The Chaos

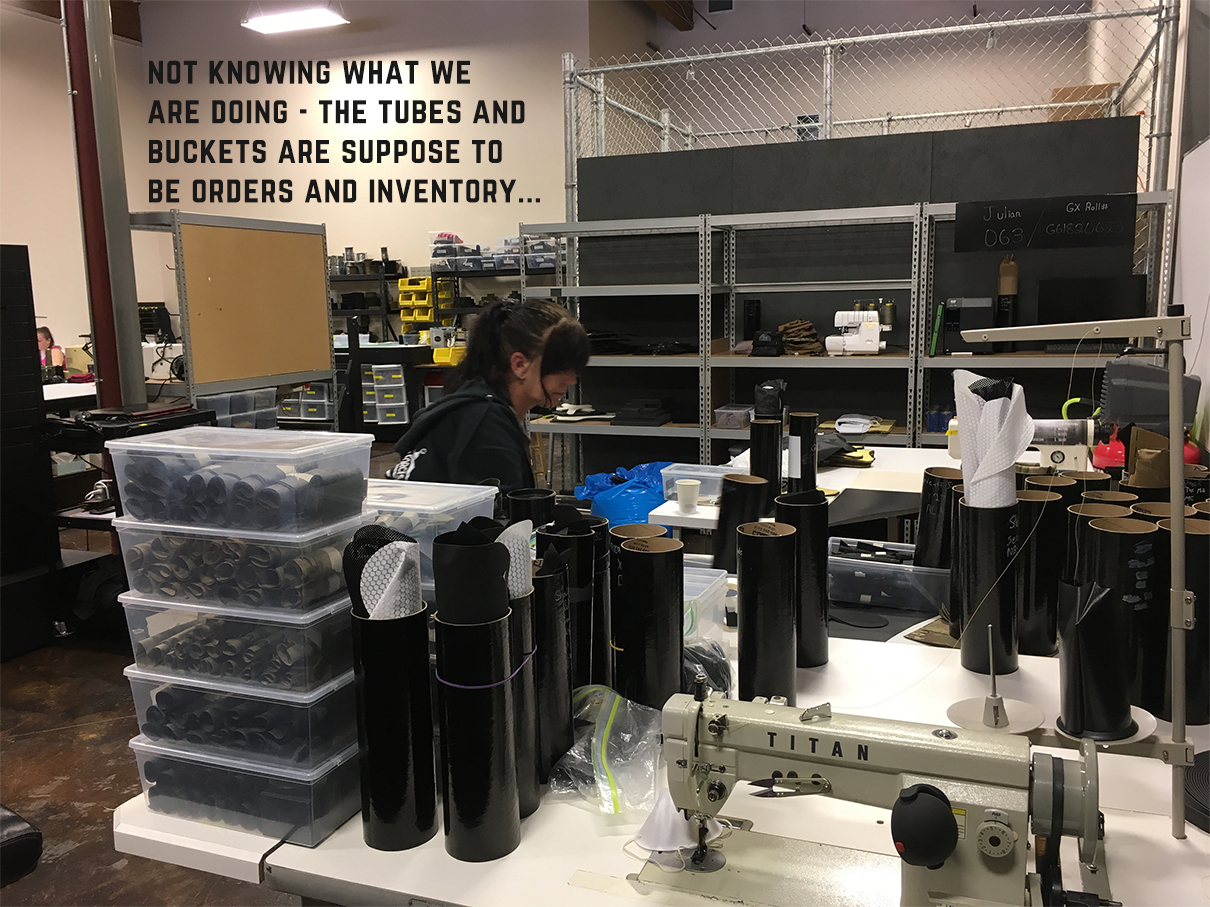

The truth is, when I started manufacturing, I didn’t have the faintest idea about proper production flow, work station design or inventory management. Our shop was chaotic: there were high drive Malinois running around knocking things over, we had obsolete finished gear mixed with half-built items, shelves crammed with materials that we’d never actually use, and workstations with missing tools scattered all over the factory floor.

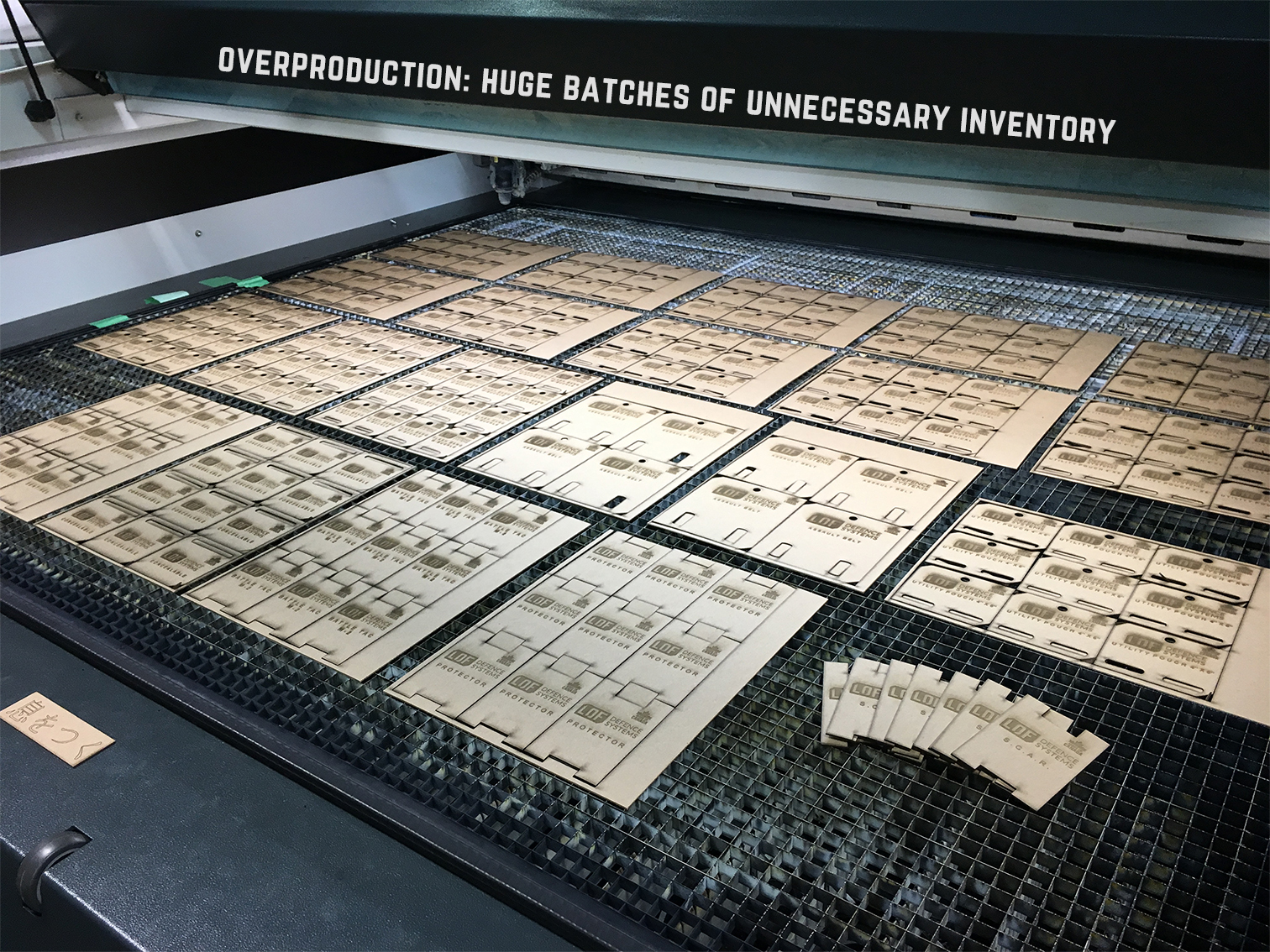

We batched everything we made, cranking out huge runs of a single product in every size and colour. Worse yet, communication on the floor was a mess, so we’d often be laser cutting or sewing something that had defects or, honestly, something no one had even ordered. Check out these product tags in the photo above, I could almost guarantee we weren't making any of those items at the time. Looking back, we only managed to stay afloat in those early days because our operation was still on a much smaller scale. Back then, our lead times were around twenty days—which is really eye opening considering our order volume was a thousand times less than what it is today.

Even with our disorganized production line, we managed to keep the company going. We genuinely thought we were doing great. We were proud of what we were doing. Then, over about six months, our social media presence started to blow up: our Instagram and Facebook posts started getting tons of attention, a few YouTube videos featuring K9 Argo (our company mascot) and the "Fur Missile Friday" series got people excited. Before we knew it, the LOF brand was getting noticed worldwide. The StreetFighter vest for K9s gained popularity in Canada, the United States, and Europe, and the orders started piling in. This was amazing news… except we never adapted our production process to handle the new demand. In a span of just a few months, our lead times shot from a few weeks to eleven months, and the worst case we had was a customer waiting over thirteen months for their order. I’ll be honest: if it weren’t for our incredibly loyal customers, many of whom were police departments and individuals who believed in us, we wouldn’t be here today. It was a nightmare trying to manage these delays, and we started getting a flood of refund requests by phone, email, and even in-person visits. I can’t blame them—I would’ve wanted my money back, too.

On a side note, looking back to the above photo: a serious question we should have asked ourselves is, why are we producing unsold inventory when our customers who paid are already waiting?

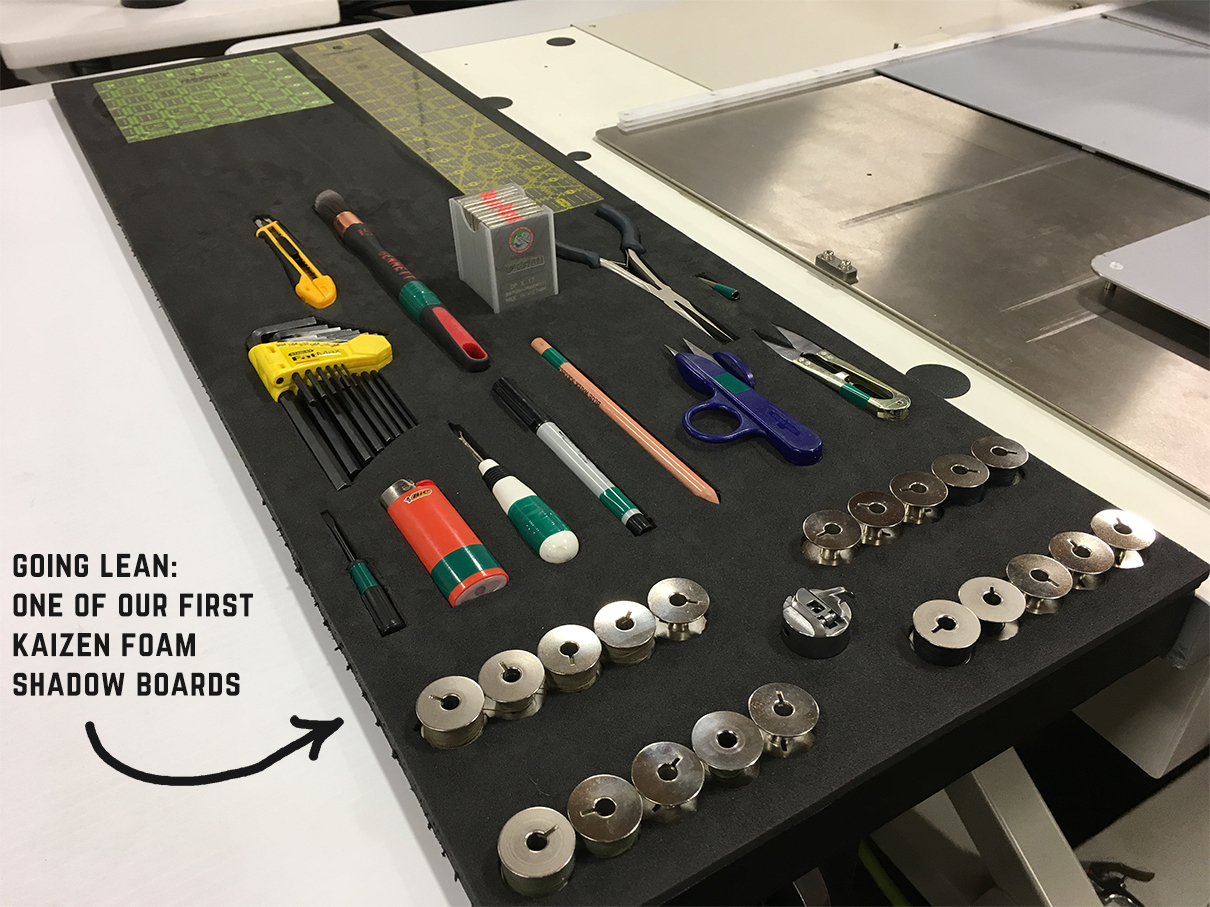

Two of my business partners ended up completely overwhelmed by this onslaught of complaints, and eventually we all sat down and had a brutally honest conversation. The meeting didn't go well...the conclusion was simple: we didn’t know what we were doing, and if we didn’t figure it the fuck out, we’d be closing our doors by the end of 2018. That day, I left the shop early to reflect on the situation. Just before I walked out, one of my business partners handed me a stack of printed pages from some random Google search—things like “Manufacturing Principles,” “10 Steps on How to Manufacture,” “Manufacturing Overseas,” and so on. Most of it didn’t help at all. But there was a short article somewhere in the papers talking about Lean Management that got my attention, specifically a guideline about “One Piece Flow” and how batch manufacturing can wreck your business.

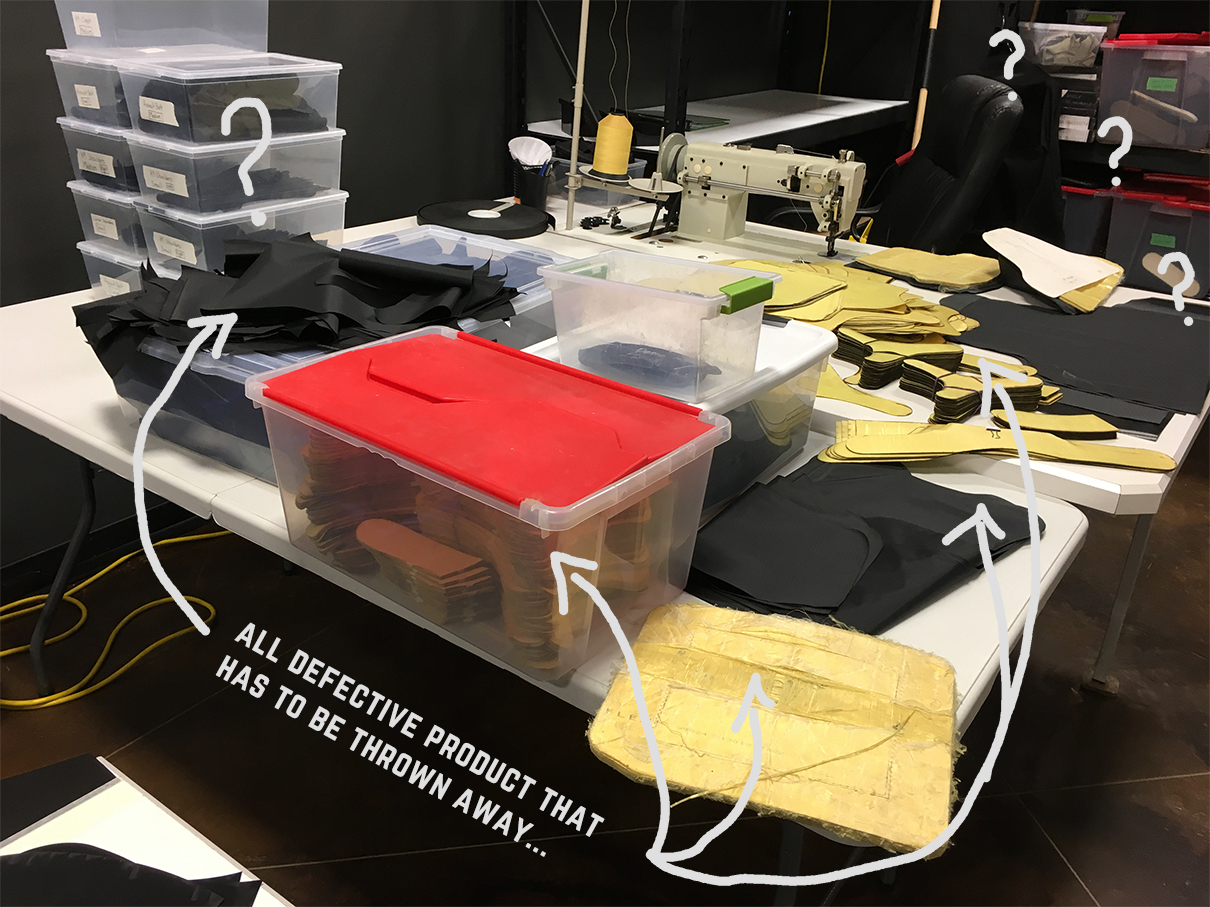

Up until that moment, the only thing I really knew about manufacturing was how to batch products in huge quantities. We’d make hundreds of AR15 pouches or K9 leads in every size and every colour, imagining we’d have them ready to ship whenever someone ordered. It seemed logical, but it led to ridiculous scenarios—like the day we decided to laser cut a big batch of blaze orange AR10 pouches in every variation (flaps, bungee retention, etc). Turns out, almost no one orders blaze orange AR10 pouches. So we’d wasted hours cutting a material that would just sit around collecting dust. Even worse, after all that cutting, transporting the material across the shop in the most inefficient way possible, organizing the inventory with poor labelling and eventually putting them into production, we discovered there was a defect in our pattern’s seam allowance. Yea...the AR-10 mags didn't fit. This meant that the entire day’s work—and the material cost—went straight into the trash. This wasn't the first time this happened, however, this time was a huge wake-up call. It was hard to throw mistakes away (it still is to this day) but the mindset at the time was, "Inventory it, we can use it later, we'll cut it down to make pistol pouches!" In a manufacturing setting, this seemingly harmless idea leads to absolute mayhem.

If my business parter wouldn't have given me those printed out documents, I wouldn't have realized we couldn’t keep doing things the way we had been. We’d grown into a company sending life-saving products around the world, but our production model was stuck in the stone age. Lean Manufacturing wasn’t just a buzzword; it was the key to building a team culture and making sure we could handle the demand for our body armour and tactical gear without driving ourselves (and our customers) insane.

We haven’t finished our journey—and we never will. If anything, even though we've been doing Lean for almost eight years, it is a journey and it still feels like we just started—but I can tell you it’s been a game-changer for LOF. Continuous improvement never ends. Embracing Lean Manufacturing has helped us keep the promise we make to every law enforcement officer, K9 handler, soldier and citizen that trust our gear in life-or-death situations.

Thank you for sticking with us as we continue figuring out how to do this right. Our mission is to keep you safe, and that means getting better at what we do, one step at a time. Stay tuned to for Part 2 of this mini blog series to find out some of the first steps we made diving into this new world of Lean Manufacturing and forgetting everything we thought we knew about running a business.

Author